Sometimes the hurdle is in the last place you might expect because you don’t see it every day or feels it’s effects personally.

You’ve paid for the catalog, you’ve paid for the marketing, you’ve found a good distributor, you had a great sales meeting and the outside salespeople are excited to go show their customers your product.

What happens next?

The end-user customer asks for a quote. Now that goes directly to the inside people at the distributor. They now have to create a quote, and when they do it, they don’t want to have to enter the same information over and over again. If one customer wants something “just like my buddy Joe got at his place” they have to standardize.

Here’s a couple of cases where the manufacturer slipped up:

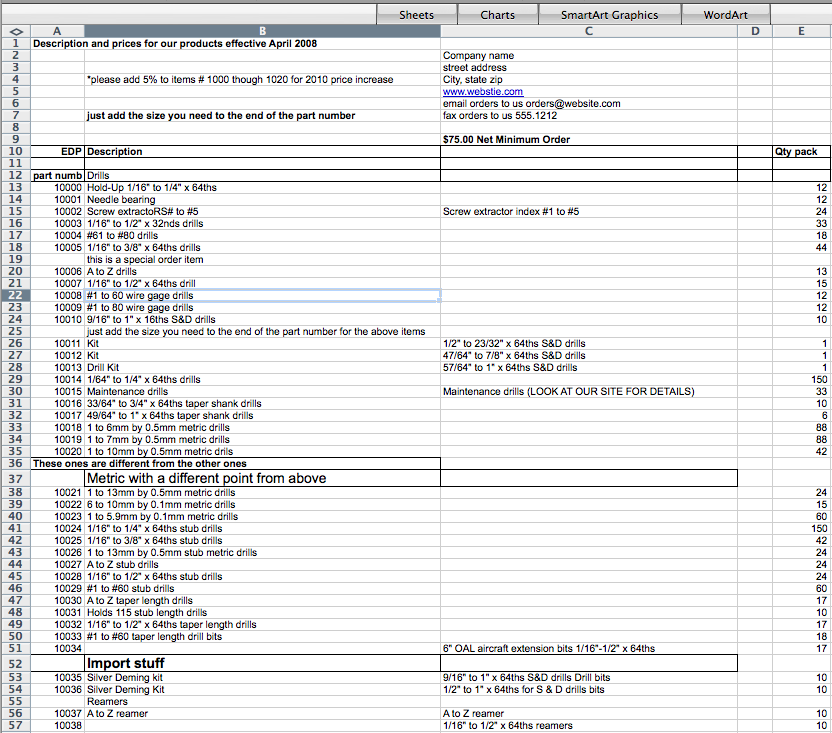

PDF issues: The Old Established Company

| They supply their price list in a PDF format. Creating price lists in PDF or MSWord is great for printing but we live in an world of databases. If there is no way to import the fields then everything has to be manually entered or was entered manually. Internally the inside sales people within the manufacturer knew that when they got the purchase orders from a particular distributor the part numbers looked different. One may have in their database “part# 32.476.198” while another had “part# 32-476-198” and still another had “part# 32 476198”. |

We are going to see more and more electronic databases being used. If you have not standardized your price lists yet you may want to get started so you have time to think it out and plan accordingly. You don’t want to be put into a position of rushing to complete only to discover you should have created it differently.

Older Software: The Storage Company

As it turns out the excel was a trainwreck: Several people had worked on the file over time. The first person did not have a good working knowledge of excel and collapsed some columns. Column B was collapsed at some point in the creation of the file and some of the product descriptions where there while other product descriptions where in Column C.

In addition to that there was a mixed standard of descriptions. As an example, one description read “Cabinet Tall 36″” while another read “Tall Cabinet 36” but they both had different part numbers.

Once again, inside sales people who are in a rush to enter orders become quickly disenchanted with vendors who make their life difficult.

If it’s not easy and intuitive, you can have the best product in the world, the best sales force, the perfect price point but you will lose orders because you’ll be branded as “They’re just tough to work with”

The “non standard” Standard

Aside from the above discussion about how computers would understand a “-G” vs. a “.g” there is a larger perception problem in play here. What may seem like a rather simple way to designate what color you want actually raises a big red flag for the distributor. They know that the way one person writes a “G” could look like a “B” to another person.

Even if the “guys on the floor” know enough to ask someone to double check, distributors know how important accurate information on the floor of a plant is to efficient delivers. It’s the real basis of “lean” “SPC” “ISO” etc. Again, what the manufacturer perceives as a “simple easy to use, ‘just add a letter’ system” what the distributor hears is

“Our shop routing process is a real mess so this vendor is probably going to be late or mess up an order at some point. I’ve got to keep an eye on them”

RSS Feed

RSS Feed